Protecting Your Harvest From Insect Infestation

Designed for Farmers – an easy to use, transportable long lasting woven sack that protects grains and cereals from most stored-product insects.

- 01

What Is GrainGard?

GrainGard® is innovative woven sack that protects grains and cereals from most stored-product insects such as large grain borers and weevils. GrainGard® is made by Adpack in partnership with ProvisionGard™. It can be used for rice, maize, wheat, flour, seeds and even animal and pet foods.

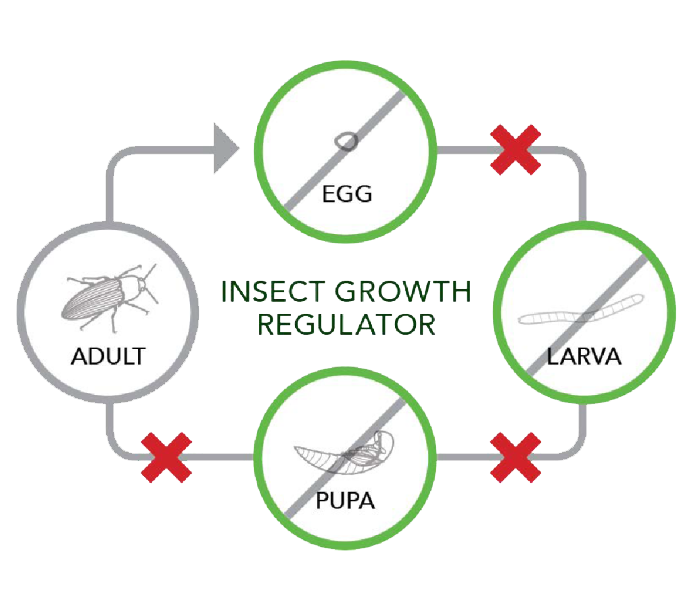

Similar to an impregnated mosquito bed net; a small amount of the special insecticide additive is incorporated into to the fibers that make up the GrainGard® bag. This treatment is called impregnation. This additive called an insect growth regulator (IGR) is non-toxic and safe for food and humans but quickly stops insects inside the grains more from coming inside, breeding and causing infestations that damage the grains.

Using a GrainGard® bag requires no special know ledge or training. You do not need to change how you pack and store your grains and cereals.

- 02

Who Makes GrainGard?

GrainGard® is made in Kenya by the leading manufacturer of ‘Gunias’ or woven sacks. Adpack makes over 40 million sacks per annum for packing rice, fertilizers, sugar, animal feeds and many other commodities.

Adpack’s advanced manufacturing technology and weaving machines ensure the GrainGard® bags are of the highest strength and durability. GrainGard® bags are also fully recyclable and reusable ensuring that they not only significantly reduce post harvest losses but also have a minimal environmental footprint.

Why Is GrainGard Needed?

A staggering one in five people in Africa and almost 30% of Kenyans face food insecurity and poor nutrition each year. This alarming statistic underscores the severity of food insecurity in Kenya and on the continent.

Kenya’s acute food insecurity is driven by multiple factors:

- Rapid Population Growth which has and continues to increase the demand for food. Agricultural capacity is strained and increasing yields to feed each new mouth has become an uphill battle.

- Climate Change is creating erratic weather patterns and persistent droughts, challenging the Kenya’s ability to grow sufficient food each year.

A multi-faceted approach is needed and reducing post-harvest loss (PHL) has been identified as a critical strategy for tackling food insecurity in Kenya and around the world. Reducing PHL focuses on optimizing the use of current resources thus making a immediate impact on the problem.

Did you know …

- That 30% of all grains and cereals harvested in Kenya are lost even before they reach the market? Over 4.5m bags of maize for example are lost each year as a result of infestations and other post harvest related losses. The amount lost each year is actually greater than the total yield of Kenya’s short rain harvest and approximately equal to one-and-a-half month’s maize consumption for the entire country.

- That many Kenyan’s just can’t afford to buy food each year – Kenya’s continuous food shortages require the importation of millions of dollars worth of grains and cereals each year (over $60m each year in maize alone). The huge amount of dollars spent importing maize for example weakens the economy and increases the price of basic food commodities to unprecedented levels each year.

- That despite smallholder farmers producing over 60% of Kenya’s food, their families often eat fewer meals or have the smallest food portions. These farmers, among the poorest in society, bear a disproportionate burden of insect infestations related post-harvest losses. Lacking proper storage facilities, they experience significant losses to rain, rot, and insect damage, leading them to sell their produce immediately after harvest when prices are lowest, making little or no profits.

By utilizing GrainGard®

- Kenya and Africa can significantly minimize food insecurity and reduce food costs.

- Farmers retain the quality of their cereals and grains which they can now store food longer, safe from infestations.

- Farmers can achieve better returns for their agricultural yields. Even holding their harvest for one extra month can bring 25% more profit for their families.

How Does GrainGard Work?

When insects are inside the GrainGard® bag they inhale and ingest the insect growth regulator (IGR), which stops their growth cycle. As a result, any insects that invade or reside in the stored product packaging will not be able to reproduce. They eventually die without ever having contributed to the growth of the insect population. This multi-action approach effectively controls both adult insects and larvae, greatly diminishing the chance of infestation and keeping stored food products secure from harm.

Rice infested by Rice Weevils

Maize/Corn Grains damaged the Lesser Grain-Borer

- 05

Farmers Are Already Choosing Graingard®

- Safe and Efficient Grain Storage: Farmers are increasingly choosing GrainGard® for its ability to securely store grain for months, protecting against pest infestations.

- Zero Losses, Higher Quality: GrainGard® virtually eliminates post harvest losses, preserving grain quality and enhancing market value and profitability.

- Optimal Selling Times: Extended storage capability allows farmers to sell their produce when market prices are most favorable, avoiding low post-harvest prices.

- User-Friendly Design: No specialized training or retreatment needed; GrainGard® is as easy to use as traditional woven sacks.

- Durable Insect Protection: The insect protection properties of GrainGard® are long-lasting and do not diminish over time, ensuring long-term storage without the need for chemicals.

- Eco-Friendly and Reusable: GrainGard® bags can be used multiple times, supporting environmental sustainability and offering economic advantages.

- 06

Institutions Are Building Graingard® Into Their Strategies to Combat Food Insecurity

- More food is needed everywhere: Food now travels from further away and storage periods are being extended increasing the chances of infestations.

- Fumigation alone has many limitations:

- Fumigation is Curative, Not Preventative: It only eliminates existing pests within a consignment but does not prevent future infestations.

- Fumigation is an Incomplete Solution: While fumigation kills live insects, it fails to destroy their eggs, which may hatch soon after treatment.

- Fumigation is costly and increasingly more every day.

- Combatting Insect Infestations: Warmer climates increase the likelihood of insect infestations, threatening food security.

- GrainGard® is pivotal in ensuring access to healthy, safe, and nutritious food, echoing Governments’ and NGOs’ dedication to combating food insecurity and guaranteeing essential nutrition.

- 07

Graingard® and Provisiongard™ are supported by decades of research

- ProvisionGard™ the active ingredient in GrainGard® has been extensively used, tested and approved worldwide for nearly 50 years to control insect populations in stored grains (like maize, rice and wheat) and other foods including meat, milk, mushrooms, peanuts.

- ProvisionGard™ has been approved by the United States Environmental Protection Agency (EPA) and meets the rigorous standards set by the U.S. Food and Drug Administration (FDA).

- ProvisionGard™ and GrainGard® are not harmful to children, birds, dogs, cats, other mammals, or bees. What differentiates this active ingredient from other widely used pesticides is that its technology is based on naturally occurring substances found only in insects.

- ProvisionGard™ has also well recognized by the World Health Organization (WHO) for its safe usage levels.

- ProvisionGard™ also is compliant European Union’s Framework-Regulation (EC) No. 1935/2004 and the Indian Food Safety and Standards (Packaging and Labeling) Regulations, 2011.

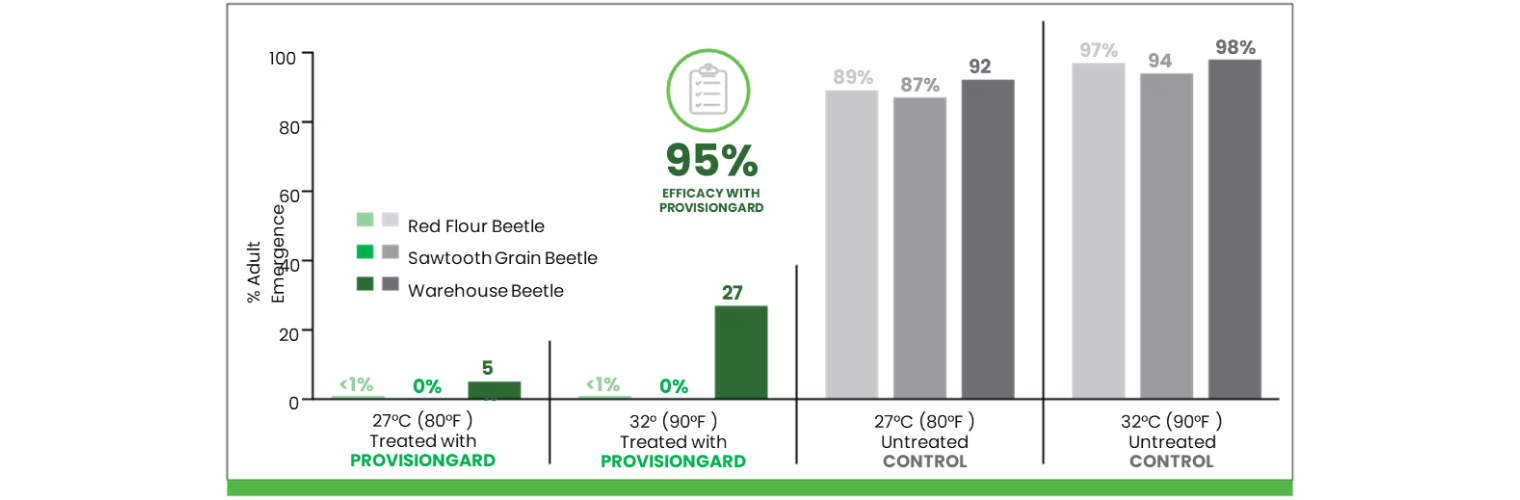

Graingard® Has More Than 95% Efficacy

GrainGard® stands out for its remarkable effectiveness in warding off a wide array of insect pests, such as larger and lesser grain borers, sawtoothed grain beetles, red flour beetles, khapra beetles, Indian meal moths, angoumois grain moths, rice weevils, among others.

During a two-year pilot procurement program, with a budget of around $600,000 USD, institutions including MIT, USAID, and USDA evaluated eight different packaging solutions. Among these, ProvisionGard™ the technology that GrainGard® is built on was selected by USAID for food packaging shipments to combat insect infestation and to cut down on shipping costs by eliminating the need for fumigation expenses. In another 2002 study performed in Brazil the impact was a 95% reduction of insects as compared

to the untreated packages.

Frequently asked questions

GrainGard® is an innovative product developed by Adpack Limited, in partnership with ProvisionGard™ technology, designed specifically to protect stored grains and cereals from damage caused by insects. Its unique feature is the incorporation of an Insect Growth Regulator (IGR), a special ingredient that disrupts the life cycle of insects, effectively preventing them from multiplying and keeping the grains safe and intact.

Yes, the durability and quality of GrainGard® bags mean they can be reused multiple times. While we recommend two uses to ensure optimal effectiveness, many of our users report using the bags up to four times successfully. This reusability factor is a testament to the longevity of the active ingredients in the bags, which remain potent against insects over time, making GrainGard® a cost-effective and eco-friendly choice for grain storage.

The safety of the active ingredient in GrainGard® bags is assured, with full approvals and compliance with standards set by key global regulatory bodies including the Environmental Protection Agency (EPA), Food and Drug Administration (FDA), and the World Health Organization (WHO). It’s non-toxic and harmless to humans, animals, and beneficial insects, focusing its effects solely on the target pest population.

GrainGard® is engineered to protect against a wide range of storage pests, including but not limited to weevils, beetles, and moths. These pests, known for their destructive impact on stored grains, find themselves unable to breach the protective barrier created by the IGR-infused bags, ensuring your grains remain healthy and free from infestation.

Adpack Limited utilizes cutting-edge technology and manufacturing processes to produce GrainGard®, ensuring each bag meets our high standards for quality and effectiveness. The integration of ProvisionGard™ technology into the fabric of the bags is carefully controlled to provide consistent, reliable protection for your grains.

For further inquiries or to learn more about how GrainGard® can benefit your operations, please contact Adpack Limited at +254 (733) 487090 or via email at graingard@adpacklimited.com. Visit our website [https://adpacklimited.com/graingard/](https://adpacklimited.com/graingard/) for additional information and resources.

GrainGard® uses a powerful approach to grain storage by incorporating IGR into the fabric of its bags. This method doesn’t just kill pests; it prevents them from growing and reproducing. When insects come into contact with the IGR-treated material, their development is halted, effectively breaking the pest lifecycle and ensuring long-term protection for the stored grains without using harmful chemicals.

GrainGard® bags are designed to last, offering up to two years of effective grain protection under the right conditions. This extended lifespan allows for repeated use over several seasons, providing reliable and consistent defense against insect infestation.

Standard GrainGard® bags are available in white, providing a clean and professional look while making it easier to identify the stored products. For those ordering in bulk, we offer the option to customize bags with your company’s logo, allowing for brand visibility and personalization of your storage solutions. This customization helps in aligning the bags with your brand identity and offers a unique touch to the storage facilities.

Choosing GrainGard® means opting for an advanced, scientifically proven method of grain protection that is both effective and environmentally friendly. Unlike traditional methods that may rely on chemical treatments or require constant maintenance, GrainGard® offers a hassle-free solution that provides long-term protection, preserves grain quality, and is safe for the environment, making it an invaluable tool for modern agriculture practices.

GrainGard® is a versatile solution suitable for a wide range of users, from smallholder farmers to large agricultural operations. By significantly reducing post-harvest losses, GrainGard® helps to increase profitability, enhance food security, and contribute to the sustainability of farming practices. Its ease of use and effectiveness make it a popular choice for anyone looking to improve their grain storage system.

GrainGard® ni suluhisho la kisasa lililobuniwa na Adpack Limited kwa ushirikiano na teknolojia ya ProvisionGard™, likilenga kulinda nafaka na vyakula vya nafaka dhidi ya uharibifu unaosababishwa na wadudu wakati wa kuhifadhi. Sifa yake ya pekee ni kujumuisha Dhibiti Ukuaji wa Wadudu (IGR), kiungo maalum kinachovuruga mzunguko wa maisha wa wadudu, kwa hivyo kuzuia uzalianaji wao na kulinda nafaka zilizohifadhiwa.

Ndiyo, ubora na uimara wa mifuko ya GrainGard® inamaanisha kuwa inaweza kutumika mara kadhaa. Ingawa tunapendekeza utumiaji wa mara mbili kuhakikisha ufanisi bora, watumiaji wetu wengi wameripoti mafanikio ya matumizi ya hadi mara nne. Hii ni uthibitisho wa uhai mrefu wa viungo hai katika mifuko, ambavyo vinabaki kuwa vyenye nguvu dhidi ya wadudu kwa muda, ikifanya GrainGard® kuwa chaguo lenye ufanisi wa gharama na rafiki kwa mazingira kwa uhifadhi wa nafaka.

Usalama wa kiungo kikuu kilichopo katika mifuko ya GrainGard® umehakikishiwa, na idhini kamili na kufuata viwango vilivyowekwa na mashirika muhimu ya kimataifa ikiwa ni pamoja na Shirika la Ulinzi wa Mazingira (EPA), Utawala wa Chakula na Dawa (FDA), na Shirika la Afya Duniani (WHO). Ni kisicho na sumu na salama kwa binadamu, wanyama, na wadudu wenye manufaa, kikielekeza athari zake pekee kwa idadi ya wadudu lengwa.

GrainGard® imebuniwa kulinda dhidi ya wigo mpana wa wadudu waharibifu wa kuhifadhi, ikiwa ni pamoja na weevils, beetles, na nondo. Wadudu hawa, wanaojulikana kwa athari zao mbaya kwenye nafaka zilizohifadhiwa, wanajikuta hawawezi kupenya kizuizi cha kinga kilichoundwa na mifuko iliyotibiwa na IGR, ikihakikisha nafaka zako zinabaki kuwa na afya na zisizo na uvamizi.

Adpack Limited inatumia teknolojia ya kisasa na michakato ya utengenezaji kuzalisha GrainGard®, ikihakikisha kila mfuko unakidhi viwango vyetu vya juu vya ubora na ufanisi. Kuunganishwa kwa teknolojia ya ProvisionGard™ katika kitambaa cha mifuko kunadhibitiwa kwa uangalifu ili kutoa ulinzi thabiti, wa kuaminika kwa nafaka zako.

Kwa maswali yoyote au kujifunza zaidi kuhusu jinsi GrainGard® inavyoweza kunufaisha shughuli zako, tafadhali wasiliana na Adpack Limited kwa +254 (733) 487090 au kupitia barua pepe graingard@adpacklimited.com. Tembelea tovuti yetu [https://adpacklimited.com/graingard/](https://adpacklimited.com/graingard/) kwa taarifa zaidi na rasilimali.

GrainGard® inatumia njia yenye nguvu ya kuhifadhi nafaka kwa kuingiza IGR katika kitambaa cha mifuko yake. Njia hii haui tu wadudu; inazuia ukuwaji na uzalianaji wao. Wadudu wakigusana na material iliyotibiwa na IGR, ukuwaji wao unasimamishwa, hivyo kuvunja mzunguko wa maisha ya wadudu na kuhakikisha ulinzi wa muda mrefu kwa nafaka zilizohifadhiwa bila kutumia kemikali zenye madhara.

Mifuko ya GrainGard® imeundwa kudumu, ikitolea ulinzi wa ufanisi kwa nafaka zako kwa hadi miaka miwili chini ya hali zifaazo. Maisha marefu haya yanaruhusu matumizi ya kurudiwa kwa misimu mingi, kutoa ulinzi wa kuaminika na wa kudumu dhidi ya mashambulizi ya wadudu.

Kawaida, mifuko ya GrainGard® inapatikana kwa rangi nyeupe, ikitoa muonekano safi na wa kiprofesheno huku ikifanya iwe rahisi kutambua bidhaa zilizohifadhiwa. Kwa wale wanaoagiza kwa wingi, tunatoa chaguo la kubinafsisha mifuko na nembo ya kampuni yako, ikiruhusu muonekano wa chapa yako na ubinafsishaji wa suluhisho lako la uhifadhi. Ubinafsishaji huu husaidia kuendana na utambulisho wa chapa yako na kutoa mguso wa kipekee kwa vituo vya uhifadhi.

Kuchagua GrainGard® kunamaanisha kuchagua njia ya kisasa, iliyothibitishwa kisayansi ya ulinzi wa nafaka ambayo ni yenye ufanisi na rafiki kwa mazingira. Tofauti na njia za kawaida ambazo zinaweza kutegemea matibabu ya kemikali au kuhitaji matengenezo ya mara kwa mara, GrainGard® inatoa suluhisho lisilo na usumbufu linalotoa ulinzi wa muda mrefu, linahifadhi ubora wa nafaka, na ni salama kwa mazingira, ikiifanya kuwa zana muhimu kwa mazoea ya kilimo ya kisasa.

GrainGard® ni suluhisho linalofaa kwa watumiaji wengi, kutoka kwa wakulima wadogo hadi operesheni kubwa za kilimo. Kwa kupunguza kwa kiasi kikubwa hasara baada ya mavuno, GrainGard® husaidia kuongeza faida, kuboresha usalama wa chakula, na kuchangia katika uendelevu wa mazoea ya kilimo. Urahisi wa matumizi na ufanisi wake hufanya iwe chaguo maarufu kwa mtu yeyote anayetaka kuboresha mfumo wake wa uhifadhi wa nafaka.

GrainGard® is an innovative product developed by Adpack Limited, in partnership with ProvisionGard™ technology, designed specifically to protect stored grains and cereals from damage caused by insects. Its unique feature is the incorporation of an Insect Growth Regulator (IGR), a special ingredient that disrupts the life cycle of insects, effectively preventing them from multiplying and keeping the grains safe and intact.

Yes, the durability and quality of GrainGard® bags mean they can be reused multiple times. While we recommend two uses to ensure optimal effectiveness, many of our users report using the bags up to four times successfully. This reusability factor is a testament to the longevity of the active ingredients in the bags, which remain potent against insects over time, making GrainGard® a cost-effective and eco-friendly choice for grain storage.

The safety of the active ingredient in GrainGard® bags is assured, with full approvals and compliance with standards set by key global regulatory bodies including the Environmental Protection Agency (EPA), Food and Drug Administration (FDA), and the World Health Organization (WHO). It’s non-toxic and harmless to humans, animals, and beneficial insects, focusing its effects solely on the target pest population.

GrainGard® is engineered to protect against a wide range of storage pests, including but not limited to weevils, beetles, and moths. These pests, known for their destructive impact on stored grains, find themselves unable to breach the protective barrier created by the IGR-infused bags, ensuring your grains remain healthy and free from infestation.

Adpack Limited utilizes cutting-edge technology and manufacturing processes to produce GrainGard®, ensuring each bag meets our high standards for quality and effectiveness. The integration of ProvisionGard™ technology into the fabric of the bags is carefully controlled to provide consistent, reliable protection for your grains.

For further inquiries or to learn more about how GrainGard® can benefit your operations, please contact Adpack Limited at +254 (733) 487090 or via email at graingard@adpacklimited.com. Visit our website [https://adpacklimited.com/graingard/](https://adpacklimited.com/graingard/) for additional information and resources.

GrainGard® uses a powerful approach to grain storage by incorporating IGR into the fabric of its bags. This method doesn’t just kill pests; it prevents them from growing and reproducing. When insects come into contact with the IGR-treated material, their development is halted, effectively breaking the pest lifecycle and ensuring long-term protection for the stored grains without using harmful chemicals.

GrainGard® bags are designed to last, offering up to two years of effective grain protection under the right conditions. This extended lifespan allows for repeated use over several seasons, providing reliable and consistent defense against insect infestation.

Standard GrainGard® bags are available in white, providing a clean and professional look while making it easier to identify the stored products. For those ordering in bulk, we offer the option to customize bags with your company’s logo, allowing for brand visibility and personalization of your storage solutions. This customization helps in aligning the bags with your brand identity and offers a unique touch to the storage facilities.

Choosing GrainGard® means opting for an advanced, scientifically proven method of grain protection that is both effective and environmentally friendly. Unlike traditional methods that may rely on chemical treatments or require constant maintenance, GrainGard® offers a hassle-free solution that provides long-term protection, preserves grain quality, and is safe for the environment, making it an invaluable tool for modern agriculture practices.

GrainGard® is a versatile solution suitable for a wide range of users, from smallholder farmers to large agricultural operations. By significantly reducing post-harvest losses, GrainGard® helps to increase profitability, enhance food security, and contribute to the sustainability of farming practices. Its ease of use and effectiveness make it a popular choice for anyone looking to improve their grain storage system.

GrainGard® ni suluhisho la kisasa lililobuniwa na Adpack Limited kwa ushirikiano na teknolojia ya ProvisionGard™, likilenga kulinda nafaka na vyakula vya nafaka dhidi ya uharibifu unaosababishwa na wadudu wakati wa kuhifadhi. Sifa yake ya pekee ni kujumuisha Dhibiti Ukuaji wa Wadudu (IGR), kiungo maalum kinachovuruga mzunguko wa maisha wa wadudu, kwa hivyo kuzuia uzalianaji wao na kulinda nafaka zilizohifadhiwa.

Ndiyo, ubora na uimara wa mifuko ya GrainGard® inamaanisha kuwa inaweza kutumika mara kadhaa. Ingawa tunapendekeza utumiaji wa mara mbili kuhakikisha ufanisi bora, watumiaji wetu wengi wameripoti mafanikio ya matumizi ya hadi mara nne. Hii ni uthibitisho wa uhai mrefu wa viungo hai katika mifuko, ambavyo vinabaki kuwa vyenye nguvu dhidi ya wadudu kwa muda, ikifanya GrainGard® kuwa chaguo lenye ufanisi wa gharama na rafiki kwa mazingira kwa uhifadhi wa nafaka.

Usalama wa kiungo kikuu kilichopo katika mifuko ya GrainGard® umehakikishiwa, na idhini kamili na kufuata viwango vilivyowekwa na mashirika muhimu ya kimataifa ikiwa ni pamoja na Shirika la Ulinzi wa Mazingira (EPA), Utawala wa Chakula na Dawa (FDA), na Shirika la Afya Duniani (WHO). Ni kisicho na sumu na salama kwa binadamu, wanyama, na wadudu wenye manufaa, kikielekeza athari zake pekee kwa idadi ya wadudu lengwa.

GrainGard® imebuniwa kulinda dhidi ya wigo mpana wa wadudu waharibifu wa kuhifadhi, ikiwa ni pamoja na weevils, beetles, na nondo. Wadudu hawa, wanaojulikana kwa athari zao mbaya kwenye nafaka zilizohifadhiwa, wanajikuta hawawezi kupenya kizuizi cha kinga kilichoundwa na mifuko iliyotibiwa na IGR, ikihakikisha nafaka zako zinabaki kuwa na afya na zisizo na uvamizi.

Adpack Limited inatumia teknolojia ya kisasa na michakato ya utengenezaji kuzalisha GrainGard®, ikihakikisha kila mfuko unakidhi viwango vyetu vya juu vya ubora na ufanisi. Kuunganishwa kwa teknolojia ya ProvisionGard™ katika kitambaa cha mifuko kunadhibitiwa kwa uangalifu ili kutoa ulinzi thabiti, wa kuaminika kwa nafaka zako.

Kwa maswali yoyote au kujifunza zaidi kuhusu jinsi GrainGard® inavyoweza kunufaisha shughuli zako, tafadhali wasiliana na Adpack Limited kwa +254 (733) 487090 au kupitia barua pepe graingard@adpacklimited.com. Tembelea tovuti yetu [https://adpacklimited.com/graingard/](https://adpacklimited.com/graingard/) kwa taarifa zaidi na rasilimali.

GrainGard® inatumia njia yenye nguvu ya kuhifadhi nafaka kwa kuingiza IGR katika kitambaa cha mifuko yake. Njia hii haui tu wadudu; inazuia ukuwaji na uzalianaji wao. Wadudu wakigusana na material iliyotibiwa na IGR, ukuwaji wao unasimamishwa, hivyo kuvunja mzunguko wa maisha ya wadudu na kuhakikisha ulinzi wa muda mrefu kwa nafaka zilizohifadhiwa bila kutumia kemikali zenye madhara.

Mifuko ya GrainGard® imeundwa kudumu, ikitolea ulinzi wa ufanisi kwa nafaka zako kwa hadi miaka miwili chini ya hali zifaazo. Maisha marefu haya yanaruhusu matumizi ya kurudiwa kwa misimu mingi, kutoa ulinzi wa kuaminika na wa kudumu dhidi ya mashambulizi ya wadudu.

Kawaida, mifuko ya GrainGard® inapatikana kwa rangi nyeupe, ikitoa muonekano safi na wa kiprofesheno huku ikifanya iwe rahisi kutambua bidhaa zilizohifadhiwa. Kwa wale wanaoagiza kwa wingi, tunatoa chaguo la kubinafsisha mifuko na nembo ya kampuni yako, ikiruhusu muonekano wa chapa yako na ubinafsishaji wa suluhisho lako la uhifadhi. Ubinafsishaji huu husaidia kuendana na utambulisho wa chapa yako na kutoa mguso wa kipekee kwa vituo vya uhifadhi.

Kuchagua GrainGard® kunamaanisha kuchagua njia ya kisasa, iliyothibitishwa kisayansi ya ulinzi wa nafaka ambayo ni yenye ufanisi na rafiki kwa mazingira. Tofauti na njia za kawaida ambazo zinaweza kutegemea matibabu ya kemikali au kuhitaji matengenezo ya mara kwa mara, GrainGard® inatoa suluhisho lisilo na usumbufu linalotoa ulinzi wa muda mrefu, linahifadhi ubora wa nafaka, na ni salama kwa mazingira, ikiifanya kuwa zana muhimu kwa mazoea ya kilimo ya kisasa.

GrainGard® ni suluhisho linalofaa kwa watumiaji wengi, kutoka kwa wakulima wadogo hadi operesheni kubwa za kilimo. Kwa kupunguza kwa kiasi kikubwa hasara baada ya mavuno, GrainGard® husaidia kuongeza faida, kuboresha usalama wa chakula, na kuchangia katika uendelevu wa mazoea ya kilimo. Urahisi wa matumizi na ufanisi wake hufanya iwe chaguo maarufu kwa mtu yeyote anayetaka kuboresha mfumo wake wa uhifadhi wa nafaka.